Guarantee Ideal Efficiency: Selecting the Right Komatsu Undercarriage Parts for Your Fleet

Guarantee Ideal Efficiency: Selecting the Right Komatsu Undercarriage Parts for Your Fleet

Blog Article

Reliable Solutions: Undercarriage Parts for Heavy Machinery

When it involves heavy equipment, the undercarriage is a vital element that commonly establishes the general performance and efficiency of the tools. Quality undercarriage parts play a significant duty in making sure the smooth procedure and durability of hefty machinery. From excavators to dozers, each tool depends greatly on its undercarriage to endure hard working problems. Nonetheless, deterioration are unpreventable, resulting in possible concerns that can hinder performance and boost upkeep expenses (komatsu undercarriage parts). In this conversation, we will certainly discover the importance of purchasing top-notch undercarriage components, common wear obstacles dealt with by heavy machinery operators, the advantages of timely substitutes, standards for choosing trustworthy suppliers, and necessary maintenance suggestions to prolong the lifespan of undercarriage elements.

Relevance of High Quality Undercarriage Components

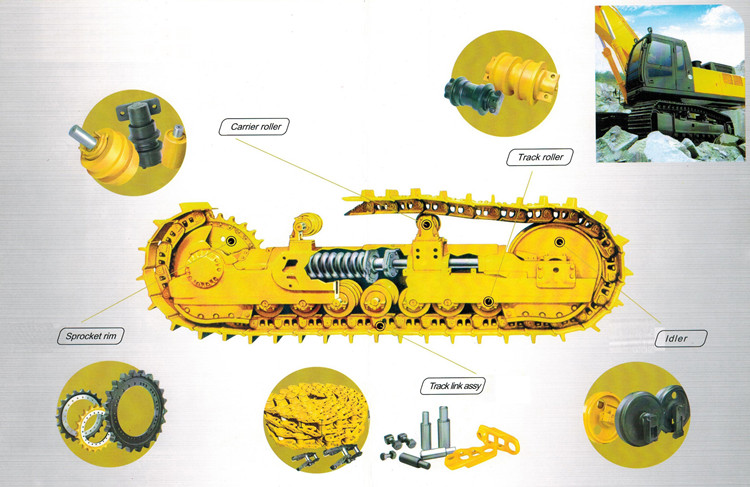

Quality undercarriage components are necessary components in making sure the durability and performance of hefty machinery. The undercarriage of devices such as excavators, excavators, and track loaders plays a crucial role in supporting the device's weight, supplying stability on different surfaces, and soaking up the influence of irregular surface areas. By buying top notch undercarriage parts, drivers can substantially prolong the life expectancy of their machinery and reduce the risk of unforeseen break downs.

One key benefit of making use of top quality undercarriage components is the improvement of general device performance. Sturdy tracks, idlers, gears, and rollers minimize friction and make certain smoother activity, eventually resulting in increased performance and effectiveness on work websites. In addition, trusted undercarriage elements reduce downtime for upkeep and repair services, permitting operators to maximize their functional hours and project target dates.

Typical Undercarriage Wear Problems

Benefits of Timely Replacement

One secret benefit of timely undercarriage component replacement is enhanced device uptime. By replacing used components before they fail, the threat of unexpected failures is decreased, lowering downtime for repair services and maintenance. This proactive technique not only keeps the hefty machinery operational yet likewise avoids prospective damages to other parts that might result from a falling short undercarriage.

In addition, replacing undercarriage parts quickly can boost general productivity. A properly maintained undercarriage makes sure optimal equipment efficiency, allowing for smoother procedure and higher performance in completing tasks. This, in turn, brings about enhanced work site productivity and price financial savings by staying clear of disruptions and hold-ups brought on by underperforming machinery. Therefore, buying prompt undercarriage component replacement is a positive method that settles in regards to enhanced effectiveness and lowered operational expenses.

Picking the Right Undercarriage Vendor

Selecting the suitable undercarriage vendor is a critical decision that significantly affects the efficiency and upkeep of hefty equipment. When selecting a vendor for undercarriage parts, additional reading numerous elements have to be considered to make certain optimum efficiency and cost-effectiveness. A provider that provides a large selection of undercarriage parts for various hefty machinery brands and models can be helpful as it provides much more choices to meet specific demands.

Moreover, evaluating the provider's customer support and assistance is crucial. A supplier that provides outstanding client solution, quick feedback times, and technical help can aid reduce downtime and make certain smooth operations. Expense is also a significant aspect to take into consideration; nonetheless, it should not be the sole factor. Stabilizing cost-effectiveness, top quality, and reliability is crucial when choosing the right undercarriage vendor for hefty equipment. By meticulously evaluating these variables, you can pick a distributor that meets your demands and contributes to the efficient performance and upkeep of your heavy equipment.

Upkeep Tips for Extended Lifespan

To ensure an extensive life-span for heavy machinery undercarriage components, carrying out an aggressive upkeep routine is important. Investing in high quality undercarriage parts from trusted providers is similarly vital for ensuring longevity. By complying with these maintenance suggestions diligently, heavy machinery proprietors can enhance the efficiency and toughness of their undercarriage parts, eventually reducing downtime and functional prices.

Conclusion

In conclusion, top quality undercarriage parts are necessary for the efficient procedure of heavy equipment. Timely replacement of used components can stop costly downtime and maintain optimum efficiency. Choosing a reliable provider and following correct upkeep methods are essential to making certain the prolonged life-span of undercarriage components. By resolving usual wear issues and spending in top quality components, hefty equipment operators can take full advantage of performance and minimize upkeep costs.

Extreme wear and tear on undercarriage components of hefty equipment can lead to considerable functional obstacles and boosted upkeep costs. Normal inspections, appropriate upkeep, and prompt substitutes of worn undercarriage parts are essential to reduce these usual wear problems and make sure the optimal performance of hefty machinery.

A provider that supplies a broad selection of undercarriage components for numerous heavy machinery brands and designs can be useful as it supplies more alternatives to satisfy particular needs.

By complying with these maintenance ideas vigilantly, heavy machinery owners can maximize the performance and durability of their undercarriage Continued components, inevitably lowering downtime and functional expenses.

Report this page